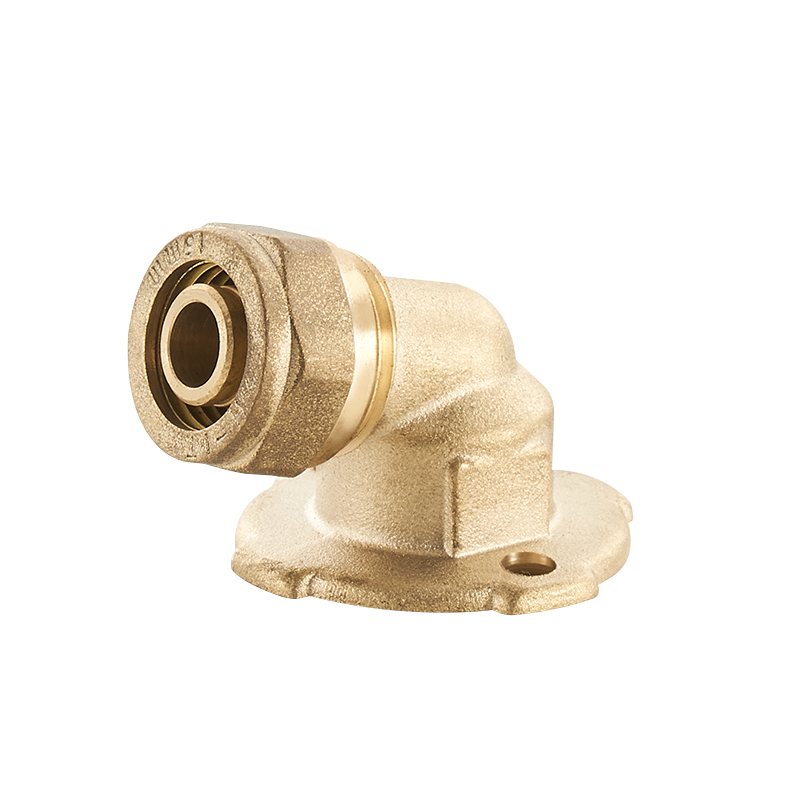

Txiv neej lub luj tshib Brass Compression haum rau Pex yeeb nkab

Optional Specification

Cov ntaub ntawv khoom

| Khoom npe | Lub luj tshib tooj dag PEX Fittings F / M Threaded | |

| Qhov ntau thiab tsawg | 15 "x 1/2", 16x1/2", 18x1/2", 20x3/4", 22x3/4", 25x1", 32 "x 1" | |

| Npog | Standard bore | |

| Daim ntawv thov | Dej, roj, roj, thiab lwm yam kua uas tsis yog-corrosive | |

| Ua hauj lwm siab | PN 16 / 200 Psi | |

| Ua haujlwm kub | -20 rau 120 ° C | |

| Ua haujlwm durability | 10,000 cycles | |

| Cov qauv zoo | ISO9001 | |

| Xaus kev sib txuas | BSP, NPE | |

| Nta: | Forged tooj dag lub cev | |

| Yam tsawg kawg nkaus | ||

| Ntau qhov ntau thiab tsawg muaj | ||

| OEM ntau lawm txais | ||

| Khoom siv | Khoom seem | Khoom siv |

| Lub cev | Forged tooj dag, sandblasted | |

| Txiv ntseej | Forged tooj dag, sandblasted | |

| Ntxig | tooj dag | |

| Rooj | Qhib lub nplhaib tooj liab | |

| Qe | N/A | |

| Ntsia hlau | N/A | |

| Ntim | Cov thawv sab hauv hauv cov thawv, thauj khoom hauv pallets | |

| Customized tsim tau | ||

Cov lus tseem ceeb

Brass Luj Fittings, Brass Pex Fittings, Dej Pipe Fittings, Tube Fittings, Brass Pipe Fittings, Plumbing Fittings, Pex Yeeb Fittings, Compression Fittings, Brass Pipe Fittings, Brass Fittings, Brass Compression Fittings, Yeeb Nkab Fittings, Pro Pex Yeeb Fittings, Plum , Pex Push Fittings

Xaiv cov khoom siv

Brass CW617N, CW614N, HPb57-3, H59-1, C37700, DZR, tsis muaj txhuas

Yeem Xim thiab Deg tiav

Brass natural xim los yog npib tsib xee plated

Daim ntawv thov

Kev tswj cov kua dej rau lub tsev thiab cov kav dej: Dej, roj, Roj, thiab lwm yam kua uas tsis yog corrosive

Brass compression fittings yuav tsum tau muab ntsia ua ke nrog lub hose los tsim ib lub hose los ua ke kom ua haujlwm.Cov hauv qab no yuav qhia cov kauj ruam installation rau koj, vam tias yuav pab tau koj.

(1) Raws li qhov yuav tsum tau ua, cov kav dej uas yuav tsum tau khaws cia yuav tsum tau khaws cia ua ntej;

(2) Txiav cov yeeb nkab nrog sawing tshuab lossis tshwj xeeb yeeb nkab txiav tshuab thiab lwm yam khoom siv raws li qhov ntev yuav tsum tau ua.Nws yog kiag li tsis pub siv melting (xws li nplaim taws txiav) los yog sib tsoo log txiav;tshem tawm cov burrs sab hauv thiab sab nraud, hlau chips thiab av ntawm cov yeeb nkab kawg;tshem tawm cov xeb tiv thaiv ntawm cov yeeb nkab txuas tus neeg sawv cev thiab cov av;tib lub sij hawm, xyuas kom meej lub roundness ntawm cov yeeb nkab;

3) Ntxig cov txiv ntseej thiab nias rau hauv cov yeeb nkab txuas ntxiv, thiab txiav ntug (me me txoj kab uas hla kawg) ntawm lub hauv ntej ntawm qhov nias yog tsawg kawg 3 hli ntawm lub qhov ncauj ntawm cov yeeb nkab, thiab tom qab ntawd ntxig cov yeeb nkab rau hauv lub qhov taper hauv qhov. lub cev sib koom ua ke kom txog thaum nws ncav cuag nws;

(4) maj mam zawm cov txiv ntoo, thaum tig lub raj kom txog thaum nws tsis txav, ces zawm cov txiv ntoo 2/3 txog 4/3 tig;

(5) Disassemble thiab xyuas seb lub ferrule puas tau raug txiav rau hauv cov yeeb nkab thiab seb txoj hauj lwm puas yog.Lub ferrule tsis tso cai kom muaj axial txav, thiab tuaj yeem tig me ntsis;

(6) Rov ua kom nruj lub txiv ntoo tom qab dhau qhov kev tshuaj xyuas.

Tiv tauj peb